|

The deep integration of new-generation information technology with manufacturing industry is an important guarantee for high-quality development of manufacturing industry. DSIC has continuously strengthened the sense of responsibility, mission and urgency to accelerate the digital transformation. With the wide application of the new generation of information technology achievements as the goal, data resources as important production factor, digital workshops as pilot, and full factor digital transformation as important driving force, DSIC has made major breakthroughs and given full play to typical demonstration role to promote "5G+ industrial Internet" ”application in shipbuilding. Since the beginning of this year, DSIC has taken informatization and standardization as primary basis, and new generation information network represented by "5G+ industrial Internet" as main carrier, to promote the deep integration of advanced digital technology with the whole process in the enterprise, improve the competitiveness of product services and production efficiency, and achieve high-quality development through technological and management innovation.

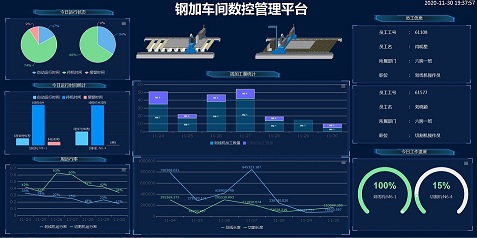

The completion of 5G network pilot application project indicates that we have taken a solid step forward in digital work. Relying on the advantages of 5G network, we have realized the network issuance of NC instructions under complex field environment in steel material processing workshop of Steel Processing Company, real-time collection of NC equipment operation status, massive data cleaning, statistics, analysis and display of phased production closed-loop management. Among them, the independent development rate of the software part is 50%, which solves the problems of different terminal data sources, large data volume, different sampling frequency, and different communication protocols. It provides a strong support for decision-making optimization such as accurate operation and maintenance, intelligent scheduling and time management.

The upgrading project of subsection digital workshop focuses on strengthening the promotion of "soft power", and builds the workshop industrial interconnection platform based on welding machine to realize real-time monitoring of welding machine status, online issuance of welding process and work order, binding of welding machine tasks, online real-time feedback of completion status, massive data storage, data statistics and analysis. Through upgrading the watching board function of the workshop to realize the weekly / daily plan, real-time operation status display of welding machines and other equipment, equipment utilization statistics, three-dimensional layout of work stations, and on-site personnel display. The mobile terminal application is constructed to realize the plan query, dispatch, receiving, feedback and equipment control within the scope of digital workshop. We have achieved rhythmic production, station level dispatching, fine management of operation, as well as the supervision and positioning of human, machine, material, law and other elements.

In the next step, based on the existing achievements, DSIC will give full play to the advantages of 5G+ industrial Internet" platform, and continue to expand the number of application devices and process application scenarios from point to area. We should not only solve the small cycle closed-loop management of internal production, but also get through the upstream and downstream data flow at different processing stages. Through digital transformation, we will build a digital management system for intelligent ships, enhance the competitiveness in shipbuilding, and lay a foundation for high-quality development .

|